|

BRHS /

OFD-Chapter 6Chapter 6. Safety measures

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

References: BS 5925: 1991, Codes of practice for ventilation principles and designing of natural ventilation EUR 9689, Commission des Communautés Européennes, Eléments pour un guide de sécurité hydrogène, Vol. 1 and Vol.2, 1985 FM Global, 2000, Property Data Sheets 7-91 « Hydrogen », September 2000 HSE 2003, Control of safety risks at gas turbines used for power generation, Plant and Machinery Guidance Note PM84, HSE Books (ISBN 0 7176 2193 6), 2003 Ivings, M.J. Lea, C.J. and Ledin, H.S., Outstanding safety questions concerning the use of gas turbines for power generation: Best Practice Guidelines for CFD, Health and Safety Laboratory Report No. CM/03/12, 2004 Ivings, M.J., Azhar, M., Carey, C, Lea, C., Ledin, S., Sinai, Y., Skinner, C., and Stephenson, P., Outstanding safety questions concerning the use of gas turbines for power generation: final report on the CFD modelling programme of work, Health and Safety Laboratory Report No. CM/03/08, 2004 Miles, S., HySafe Deliverable D49, 2006. NSS 1740.16, National Aeronautics and Space Administration, “Safety standard for hydrogen and hydrogen systems”, Guidelines for hydrogen system design, materials selection, operations, storage, and transportation. February 1997 |

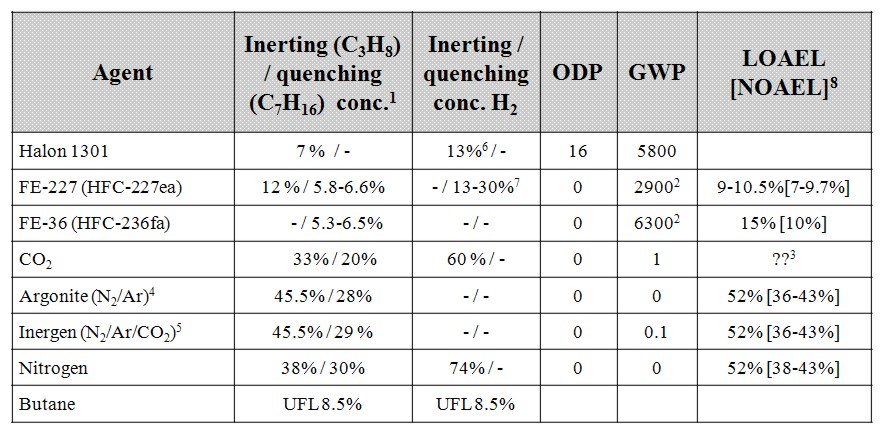

Inerting is defined as the replacement of a sufficient proportion of oxygen contained in a gaseous atmosphere by an inert gas, to make it impossible for the atmosphere to be ignited or a flame to propagate. It is an important way to prevent the formation of explosive atmospheres, particularly for hydrogenated atmospheres. However, it must not be forgotten that inerting can be dangerous for workers because of the asphyxiating property of inert gas. Although we will focus here only on injection of a gaseous inert gas, it must be mentioned that in some applications, foams can be used. The latter has been designed for use on offshore installations for hot work, i.e. welding on process systems, (Anon, 1997).

The conditions which must be strictly complied with for a reliable and safe inerting are relative to the following features:

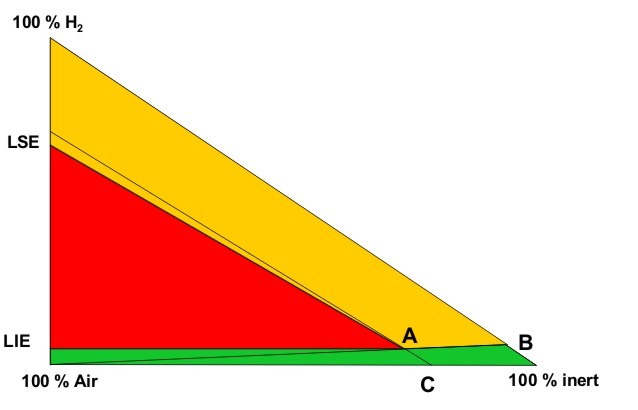

These conditions are fully described in the European document entitled “Guidance on inerting for the prevention of explosions” (prEN/TR 15281, 2005). The conditions for an hydrogenated atmosphere to be inert can be derived from a triangular diagram representing the Hydrogen-Air-Inert mixtures. Such a schematic diagram is given on Figure 1.

On this diagram, the apexes of the triangle correspond to one of the 3 pure gases:

The left side of the triangle corresponds to binary air-hydrogen mixtures : the currently accepted values for the Lower Explosion Limit (LEL) and the Upper Explosion Limit of hydrogen in air for normal atmospheric conditions have been placed on this side (LEL = 4 % vol. and UEL = 75 % vol.). The explosion area looks like a rectangular triangle (red area) : A is the apex of this area. Its lower side can be considered as parallel to the air-inert mixtures side. Its hypotenuse is almost parallel to hydrogen-inert mixtures side. The following lines have been drawn:

From the explosion diagram, the following concepts can be introduced

The Limiting Air Concentration (LAC) is the lowest air concentration of a hydrogen-air-inert mixture under which any hydrogen-air-inert mixture cannot be ignited: it corresponds to the air content of C and depends on the nature of the inert gas.

The Limiting Oxygen Concentration (LOC) is the lowest oxygen concentration of an hydrogen-air-inert mixture under which any hydrogen-air-inert mixture cannot be ignited and it can be derived from the concentration of oxygen in air : LOC = 0,209 LAC

The triangular diagram for ternary Hydrogen-Air-Inert mixtures comprises 3 coloured zones:

The ratio xinert/xH2, calculated from the co-ordinates of B, corresponds to the limiting ratio for absolute inert mixtures. As an example, taking nitrogen as the inert gas, the ternary diagram for Hydrogen-Air-Nitrogen mixtures is given in Figure A2 of the standard prEN14756 “Determination of LOC for gases and vapours” (prEN 14756, 2005) for 20°C and ambient pressure. This diagram has been experimentally determined in a 14 litre sphere according to EN 1839 standard “Determination of explosion limits of gases and vapours” (EN 1839, 2004) as described in (Schröder, 2002).

On this diagram, the following values can be derived:

Inerting consists in reducing the oxygen concentration of the atmosphere to be inerted to the lowest practical level, but it should always be less than the LOC. Typically for hydrogen, whatever the inert gas, an oxygen concentration equal to or less than 2% vol. should be used. There are several methods of inerting systems where hydrogen is to be used and the main ones are:

Further information on inerting methods in general are available in the in the CEN document (prEN/TR 15281, 2005). Where hydrogen is concerned, the requirements of the inerting system are more stringent due to several factors, including the extreme sensitivity of hydrogen to ignition, its very wide explosive limits, and its unusually low minimum oxygen for combustion. When inerting a system to contain hydrogen, it is best to use a technique which also leak tests the system as a routine part of the inerting. This can be accomplished by the use of a pressure or vacuum leak test as a part of the pressure or vacuum purging regime.

This involves pressurising the system with inert gas, and relieving back to atmospheric pressure. A pressure test can be incorporated by isolating the inert gas supply after pressurising, and determining whether the pressure falls after a period of time. As hydrogen has a very small molecular size, it is best to use helium when leak testing, as it has a similar molecular size.

When pressure-swing inerting a system, it is best to measure the oxygen concentration after inerting to confirm that the required oxygen level has actually been reached. Depending on the complexity of the system, such as a branched system or several interconnected vessels, it may be necessary to measure the oxygen concentration at several points within the system, to ensure that adequate mixing of the inert gas and the air initially present. This also applies when removing hydrogen from a closed system prior to the admission of air.

This uses exactly the same principles as the pressure-swing inerting. It involves the evacuation of a closed system and restoration to atmospheric pressure by the admission of inert gas. It is useful where a system can withstand vacuum but cannot withstand pressure, such as glass vessels.

Instead of a pressure leak test, a vacuum leak test should be applied, by isolating the vacuum from the system and measuring the rate of pressure rise. Even the best systems will eventually allow some air in, so provision should be made for vacuum systems to have the oxygen content measured, so that the system can be re-inerted before the inevitable air in-leakage makes the atmosphere within the system explosive.

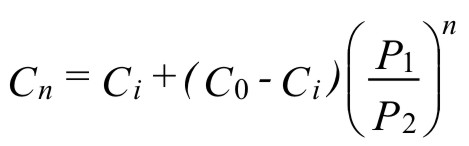

The number of pressure-swing or vacuum-swing cycles can be calculated from the equation (1):

( 1 )

( 1 )where:

n = number of pressure-swing or vacuum-swing cycles

Cn = oxygen concentration after n purges

Ci = oxygen concentration in the inert gas

C0 = initial oxygen concentration

P1 = lower purge pressure (absolute)

P2 = upper purge pressure (absolute)

Where systems can be neither evacuated nor pressurised, a flow-through technique can be used, which involves the replacement of an oxidant by a continuous flow of inert gas into a system which is vented to atmosphere. This is less efficient, and great care is required to ensure that adequate purging is achieved. A high flow rate is required to ensure adequate mixing.

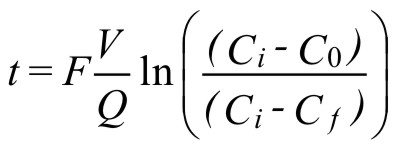

The time required to purge a given volume can be determined from the equation (2) :

( 2 )

( 2 )where:

t = time required for purging

V = system volume

Q = inert gas flowrate

F = safety factor for purging

Cf = oxygen content after flow purging

C0 = initial oxygen content

Ci = oxygen content of inert gas

t, V, and Q may be in any set of consistent units.

The inlet and outlet of the inert gas (place and geometry) should be chosen in order that:

When using a flow-through technique, the safety factor can be determined by measurement of the oxygen concentration in the gas stream being vented. Typical values of the factor F would be 1 for a single straight pipe fed at one end and vented at the other, to a value of 5 or more for a complex vessel system with poor mixing. Where a system is branched, it will be necessary to vent from the ends of all the branches to ensure that no pockets of oxygen remain. This makes flow purging the worst method of all.

This method relies on using an inert gas of significantly different density to that which is to be purged, and where significant mixing does not take place. It is used typically on the inerting of very large vessels, where it would not be possible to ensure adequate mixing if an inert gas of substantially the same density were to be used.

There is no safe inerting if the inert state of the system is not controlled and it is particularly true for hydrogen. There are two types of method for ensuring that the inert state of the system is maintained:

This method infers that the atmosphere is inert by reference to some other parameter, which allows an inference to be drawn that the atmosphere is inert. An example of this is where a system is pressure-swing inerted using Equation (1). If the number of purges is carried out correctly it can be inferred that the oxygen concentration will be correct. This is probably adequate for a simple single vessel which is pressure-swing purged. However, where a complex, branched system is pressure-swing purged, it is quite feasible that the ends of some of the branches will not be adequately purged, as the pressurising inert gas simply compresses the air trapped in the branch without mixing, so that when the pressure is released, the air expands again. Consequently, although the correct number of purges may have been applied, the system has not been fully inerted.

This can be improved by venting the pressurised system through each branch, to ensure that all the air is swept out. This can be proved by the use of a portable oxygen analyser used to measure the oxygen concentration of the gas vented from each branch. Once a system has been successfully inerted and the oxygen content found to be sufficiently low at all points within it, then it can be inferred that using exactly the same purging regime will also reproduce the same inert conditions. The disadvantage with inferring that the inerting regime is the same is that not all changes may be noticed and recognised. Hence there is a danger that the inerting may not be satisfactory, yet there will be no information to suggest that it is not successful.

This method actually measures the oxygen content of the atmosphere using a suitable oxygen sensor, and hence if there is any in-leakage of air, it is immediately detected. There are several potential problems with direct measurement. Firstly, there is the potential to measure the oxygen content at a single point, so that in a branched or complex system the sensor may not detect a change in oxygen content elsewhere in the system. This can be overcome by the use of multiple sensors. Where there are multiple sensors, these can be configured such that each reads continuously, or sequentially, so that each sensor is polled periodically. Any increase of oxygen is then detected with a maximum delay of the time between sequential readings.

The sensors have to be suitable for the duty that they have to perform, so that they are not poisoned by materials within the system. Similarly, blockages in the sensors may reduce their sensitivity or response time. Ideally, sensors should be calibrated regularly and a duplicate sensor should be used during the calibration. The major advantage with direct measurement is that oxygen ingress is usually detected very quickly, allowing safety systems to shut down the process or re-inert the system. However, where a system is automatic and reliant on the detectors working correctly, it will be necessary to ensure that the reliability is adequate.

Where hydrogen is routinely vented to atmosphere, it will be necessary to consider the potential for it to ignite. Unless it is diluted with inert gas until it is absolutely inert, it will be necessary to deal with the formation of an explosive atmosphere around the open end of the vent. As the minimum ignition energy is very low, it is likely that it will not be possible to exclude all potential ignition sources. Consequently, it will be necessary to assume that the hydrogen-air mixture will ignite, and suitable precautions will need to be taken to deal with the over-pressure produced. This may involve determining the extent of the dilution.

| References

prEN/TR 15281 “Guidance on inerting for the prevention of explosions” (2005) prEN 14756 “Determination of limiting oxygen concentration (LOC) for gases and vapours” Annex A2 (2005) EN 1839 “Determination of explosion limits of gases and vapours” (2004) Schröder, V. “Flammability limits of Hydrogen and Hydrogen/Methane mixtures” Nr. 253, NW Verlag, Bremerhaven 2002 (ISBN 3-89701-733-4) Anon, Nitrogen Foam Inerting, BJ Services, 1997 |

A recombiner is a device that promotes the recombination of hydrogen with oxygen - usually available as a constituent of air - forming water. As such, this device provides a hydrogen sink and may serve to avoid, remove or at least to slow down the formation of flammable mixtures caused by the accidental ingress of hydrogen into a closed area.

Recombiners can generally be classified into active and passive devices. Active recombiners use heat to initiate the conversion. Passive recombiners make use of the effect that hydrogen and oxygen react already at low temperatures and even beyond conventional concentration limits in an exothermal reaction in the presence of catalysts such as platinum or palladium. Appropriate measures (e.g. system design) need to be taken to prevent the system temperatures from exceeding the self-ignition temperature. This might cause an unintended ignition due to the exothermal reaction at elevated hydrogen concentrations. Without appropriate measures, the use of recombiners is limited to mixtures below the ignition limit (K. LEDJEFF, 1987).

As of today, hydrogen is primarily used in industrial scale in designated areas where the risk of formation of flammable mixtures may be reduced by design or where venting can easily be applied. As a consequence, only few specific application fields exist where recombiners are used. Only very few systems available off the shelf. With the use of hydrogen in ‚any surrounding in an increasing number of mobile applications an added need for specific recombiner systems may be expected.

Today, the main application fields are

New applications of recombiners or more generally catalytic recombination surfaces are also appearing, such as BMW’s boil-off management system.

During charging processes in batteries hydrogen and oxygen are produced and released. This may become a safety problem when dealing with large battery sections or when using batteries in a closed area like for example submarines.

Recombiner systems have been developed by VARTA for batteries (K. LEDJEFF, 1982) as well as for use in submarines providing conversion capacities of 200 L/h (VARTA, year unknown). Recombiners for batteries, so-called ‘Hydrocaps’ are also available from Hydrocap Corp. (USA). These catalytic caps replace battery cell caps and reduce water-loss of batteries as well as the risk of gas explosions outside the battery.

Recombiner systems have been developed by VARTA for batteries (K. LEDJEFF, 1982) as well as for use in submarines providing conversion capacities of 200 L/h (VARTA, year unknown). Recombiners for batteries, so-called ‘Hydrocaps’ are also available from Hydrocap Corp. (USA). These catalytic caps replace battery cell caps and reduce water-loss of batteries as well as the risk of gas explosions outside the battery. In nuclear reactors recombiners are used to remove hydrogen that is produced in service (Boiling water reactors (BWR), active recombiners) or possibly released during a severe accident (Light water reactors, passive autocatalytic recombiners).

Active thermal recombiners are used with gas capacities of 100 m³/h. The inlet gas is heated up to 700°C and above initiating the recombining reaction. The product gas is cooled before leaving the device. Thermal recombiners are manufactured by Siemens (Germany) and AECL (Canada).

Catalytic recombiners for use in nuclear reactors are manufactured by the companies Framatome-ANP (France), NIS (Germany), AECL (Canada), and Electrowatt-Ekono AG (Switzerland).

Catalytic recombiners need usually a minimum concentration of about 0.5 vol.% for start-up. As passive recombiners are self-feeding devices, the conversion rate depends on the self-generated throughput that depends on the catalyst temperature. In known systems typical flow velocities are between 0.5 and 1.0 m/s. In order to keep the system active over long periods some devices propose to be kept in a sealed environment to prevent the catalyst from being spoiled (poisoned) by the atmosphere.

Detailed information on the long term research (qualifying tests, experimental studies) that has been performed in the nuclear field with extensive bibliographical references are given in (W. ZHONG, 2001) and (E. BACHELLERIE, 2002).

|

Reference and sources K. Ledjeff. Elimination of hydrogen or oxygen from explosive mixtures by catalytic techniques. Int. J. Hydrogen Energy, Vol. 12, No. 5, pp. 361-367, 1987 K. Ledjeff, A. Winsel. Catalytic hydrogen/oxygen recombiner with self-limitation. J. Power Sources, Vol. 12, pp. 211-227, 1982 VARTA. Hydrogen elimination technology. Information brochure W. Zhong (Ed.). Mitigation of hydrogen hazards in water cooled power reactors. IAEA-TECDOC-1196, IAEA, Vienna, ISSN 1011-4289, 2001 E. Bachellerie et al. State-of-the-art report on passive autocatalytic recombiners - Handbook guide for implementing catalytic recombiners. EC Project PARSOAR, Contract FIKS-CT1999-20002, Technicatome company report, Technical note TA-185706 Ind. A., June 2002 |

There are three basic methods of protection:

The choice of a specific protection method depends on the degree of safety needed for the type of hazardous location (Zone 0, Zone 1 or Zone 2) in order to have the lowest probability value for an eventual simultaneous presence of an adequate energy source and a dangerous concentration level of an hydrogen/air mixture.

None of the protection methods can provide absolute certainty of preventing an explosion. The most efficient precaution is to avoid electrical apparatus in hazardous locations. Only when there is no alternative should this application be allowed. Other important factors to be considered are the size of the apparatus to be protected, the flexibility of the system, the possibility of performing maintenance, the installation cost, etc.

Explosion-proof enclosure: this protection method is the only one based on the explosion containment concept: in this case, the energy source can come in contact with the hydrogen/air mixture. But, even if the explosion is allowed to take place, it will remain confined in an enclosure specially designed to resist the overpressure, and thus preventing the propagation to the surroundings. This kind of protection is applicable only to equipments located in Zone 1 & 2, not in Zone 0. In Europe, CENELEC and IEC standards refer to this protection methods with the symbol “Ex "d" ”. The reference standard is the EN 50018 (EN 50018, 2000).

Pressurization protection method: pressurization is a protection method based on the segregation concept. This method prevents the penetration of the hydrogen/air mixture into the enclosure containing all the electrical parts that might generate sparks or dangerous temperatures. A protective gas (clean air or inert gas) is contained inside the enclosure, with or without continuous flow, in order to maintain a pressure slightly greater than the external atmosphere. This kind of protection is applicable only to equipments located in Zone 1 & 2, not in Zone 0. In Europe, CENELEC and IEC standards refer to this protection methods with the symbol “Ex "p" ”. The reference standard is the EN 50016 (EN 50016, 2002).

Encapsulation protection method: the encapsulation protection method is based on the segregation of those electrical parts that can cause the ignition of a dangerous mixture, by putting them in resins that are resistant to the specific ambient conditions. This technique is often used as a complement to other protection methods. This kind of protection is applicable only to equipments located in Zone 1 & 2, not in Zone 0. In Europe, CENELEC and IEC standards refer to this protection methods with the symbol “Ex "m" ”. The reference standard is the EN 50028 (EN 50028, 1999).

Oil-immersion protection method: the oil-immersion protection method is based on the submersion of all electrical parts in oil, which prevents the external flammable hydrogen/air atmosphere from going in contact with the electrical components. The most common application is for static electrical equipments, such as transformers, or where there are moving parts, such as transmitters. This method is not suitable for process instrumentation or for apparatus that requires frequent maintenance or inspections. This kind of protection is applicable only to equipments located in Zone 1 & 2, not in Zone 0. In Europe, CENELEC and IEC standards refer to this protection methods with the symbol “Ex "o" ”. The reference standard is the EN 50015 (EN 50015, 1998).

Powder-filling protection method: this protection method is similar to the oil-immersion one, except that the segregation is accomplished by filling the enclosure with powdered material so that an arc generated inside the enclosure will not result in the ignition of the dangerous atmosphere. The filling material that is generally used is quartz powder, and its granularity must comply with the standard. This kind of protection is applicable only to equipments located in Zone 1 & 2, not in Zone 0. In Europe, CENELEC and IEC standards refer to this protection method with the symbol “Ex "q" ”. The reference standard is the EN 50017 (EN 50017, 1998).

Increased safety protection method: this protection method is based on the prevention concept. Specific measures are applied to the electrical apparatus in order to prevent, with an high safety margin, the generation of excessive temperatures or of arcs and sparks inside and outside the apparatus during normal conditions. This technique can be used for the protection of terminals, electrical connections, lamp sockets and squirrel gauge motors, and is often used in combination with other methods of protection. This kind of protection is applicable only to equipment located in Zone 1 & 2, not in Zone 0. In Europe, CENELEC and IEC standards refer to this protection method with the symbol “Ex "e" ”. The reference standard is the EN 50019 (EN 50019, 2000).

Intrinsic safety protection method: intrinsic safety is the protection method most representative of the prevention concept and is based on the principle of limiting the energy stored in an electrical circuit. An intrinsically safe circuit is virtually incapable of generating arcs, sparks or thermal effects that are able to ignite an explosion of hydrogen/air mixture, both during normal operation and during specific fault conditions. According to the CENELEC EN 50020 standard, two categories of intrinsic safety (Ex "ia" and Ex "ib") are specified, defining the number of faults allowed for specific classifications and the safety coefficients to be applied during the design phase. The kind of protection Ex “ia” is applicable to equipment located in Zone 0, 1 & 2, while the Ex “ib” only to equipment located in Zone 1 & 2, but not in Zone 0. The reference standard is the EN 50020 (EN 50020, 2002).

Special protection method: originating in Germany and standardized in the United Kingdom, this protection method is not covered by any CENELEC or IEC standard and is not recognized in North America. It was developed to allow certification of apparatus that is not developed according to any of the existing protection methods, but can be considered safe for a specific hazardous location. This location must undergo appropriate tests or a detailed analysis of the design. The use of the special protection method is generally applied to Zone l & 2; however, Zone 0 certification is not excluded.

Mixed protection methods: in the process instrumentation field, the use of several protection methods applied to the same apparatus is a common practice. For example, circuits with intrinsically safe inputs can be mounted in pressurized or explosion-proof enclosures. Generally, this mixed system does not present installation difficulty if each of the protection methods is appropriately used and is in compliance with the respective standards.

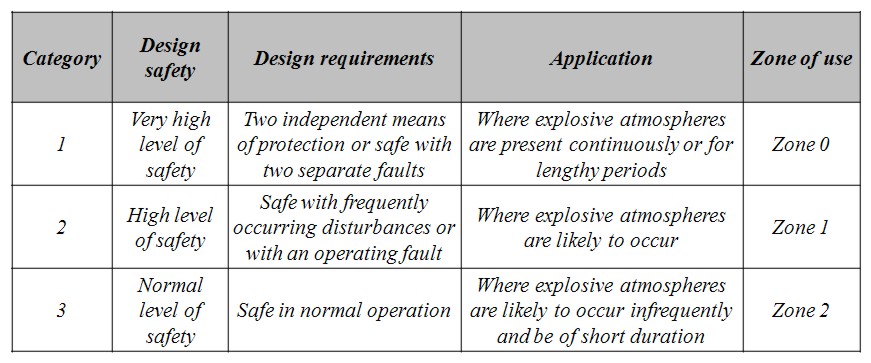

Equipment categories The categories of a piece of equipment, suitable for installation in a potentially explosive atmosphere, indicate its design safety level and requirements, as well as its allowed applications and locations (Zone). According to the ATEX Guidelines (ATEX Guidelines, 2000), for Group II (defined as “equipment intended for use in places different from underground parts of mines, and from those parts of surface installations of such mines), the category depends on the localization of the product (Zone) and whether a potentially explosive atmosphere, is always present, or is likely to occur for a long or a short period of time. The following table shows the relationship between equipment category and safety requirements, as well as allowed applications and locations (Directive 1994/9/EC).

Table 0-1: ATEX Group II Categories and Application

|

References and sources EN 50018, Electrical apparatus for potentially explosive atmospheres - Flameproof enclosure 'd', CENELEC, 2000. EN 50016, Electrical apparatus for potentially explosive atmospheres - Pressurized apparatus "p", CENELEC, 2002. EN 50028, Electrical apparatus for potentially explosive atmospheres - Encapsulation “m”, CENELEC, 1999. EN 50015, Electrical apparatus for potentially explosive atmospheres - Oil immersion “o”, CENELEC, 1998. EN 50017, Electrical apparatus for potentially explosive atmospheres - Powder filling “q”, CENELEC, 1998. EN 50020, Electrical apparatus for potentially explosive atmospheres – Intrinsic safety “i”, CENELEC, 2002. ATEX Guidelines (First Edition), Guidelines on the application of Council Directive 94/9/Ec Of 23 March 1994 on the approximation of the laws of the Member States concerning equipment and protective systems intended for use in potentially explosive atmospheres, May 2000. Directive 94/9/EC of the European Parliament and the Council of 23 March 1994 on the approximation of the laws of the Member States concerning equipment and protective systems intended for use in potentially explosive atmospheres, Official Journal L 100, 19/04/1994 P. 0001 - 0029. |

A hot surface can exist during normal operations or may occur as a result of mechanical distress (friction) in machinery such as pumps or motors. “Hot surfaces” includes both hot spots and hot plate ignition. Ignition of a gas or vapour air mixture by a hot surface is a manifestation of auto-ignition. A boundary layer of this mixture in contact with the hot surface if heated sufficiently will result in a spontaneous ignition.

Apart from hot surfaces, open flames (and hot work) can also trigger an explosion. They will be dealt with in this chapter.

For ignition to occur on a hot surface, its temperature shall be greater than the gas auto-ignition temperature. Therefore, for hydrogen, hot surfaces or hot spots temperatures shall not go beyond 560°C. This value is rather high in comparison with most combustible gases and vapours. However, unlike most combustible gases, experience has shown (MECHEX EU project) that hydrogen/air ignition by hot surfaces will happen at temperature very close to the auto-ignition temperature even for a few mm2 hot surface .

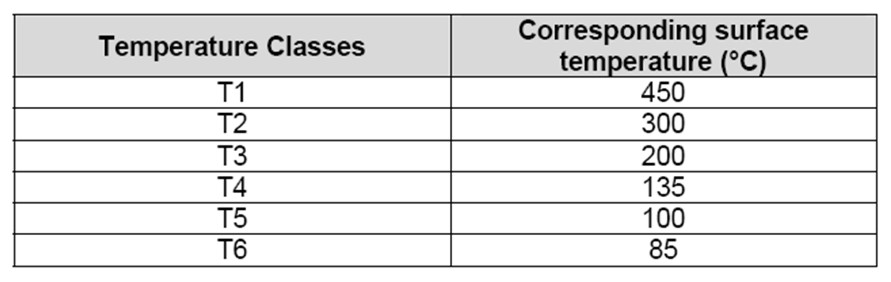

The control of hot surfaces during normal operations necessitate the selection of electrical and non-electrical equipment with care. Electrical and non-electrical equipment marking incorporates a temperature class (ranging from T1 to T6) as detailed in the table below.

Table 2: Class temperature according to EN5014 or EN 60079-9?

As an example, surface temperatures of equipment belonging to the class T2 does not go beyond 300°C. In order to prevent ignition by hot surfaces, the surface or hot spot temperature of any equipment should not exceed the gas auto-ignition temperature. Hence, the maximum tolerable surface temperature when handling hydrogen is around 580°C. Therefore, equipment belonging to class 1 and above are appropriate for hydrogen use.

As far as mechanical ignitions are concerned, they are generally the result of mechanical distress (friction) under abnormal or fault conditions. Analysis of the physical processes that lead to mechanical ignition shows that there are at least three key stages from production of heat, transfer of heat to the surrounding explosive atmosphere and finally the ignition itself (Hawksworth).

In general, the friction processes that need to be considered are rubbing (long duration friction between surfaces producing a hot surface), grinding (long duration friction producing hot surfaces and sparks) and impact (short duration friction producing short duration transient hot surfaces and sparks), or a combination of these.

Ignition by friction clearly depend on the temperature generated in the contact zone. For grinding and rubbing, the temperature at contact point depends on the rubbing speed and the contact pressure. Tests have demonstrated ignition down to speeds of 0.7 m/s (0.7 kW friction energy). In that case, ignition is triggered by the hot surface, few sparks being produced under these low speed conditions. (Hawksworth).

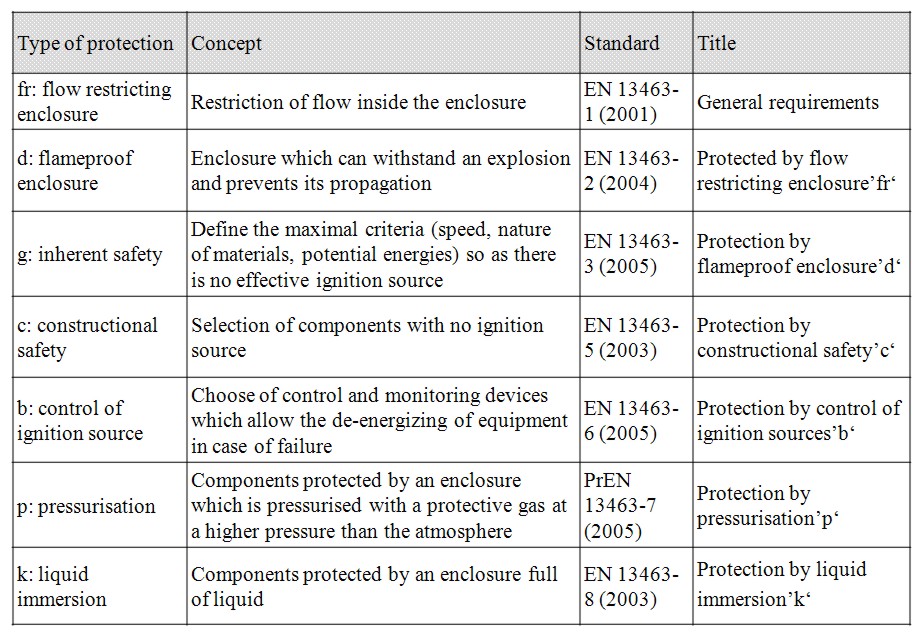

Control of mechanical ignition therefore necessitates careful design of equipment. It includes for instance to limit the rotating speed, to provide a sufficient distance between fixed and rotating parts. Temperature sensors may also be installed on mechanical equipment to detect any temperature deviation that necessitates to switch off the equipment. European standards propose various design options to prevent ignition by mechanical equipment as detailed in the table below.

Table 3: Type of protection for mechanical apparatus used in potentially explosive atmosphere

For impact, experience indicates that impact energies as small as a couple of Joules are sufficient to ignite a hydrogen/air mixture. If we admit this rough evaluation it means that a solid object falling from man height could cause hydrogen ignition (Proust). Therefore, sufficient impact temperature can eventually result from the use of hand tools (falling tool, hammer…).

The use of hand tools made of bronze enriched with few percent of beryllium (to give them sufficient hardness) are known as spark free tools. They are of common use in gas industries (natural gas distribution). However, the absence of spark does not guarantee that hydrogen/air explosive atmosphere will not be ignited (guide hydrogène). Indeed, the temperature reached at the contact point is the main driving cause to trigger an ignition (even when sparks are produced).

Therefore, it is a very delicate issue to select the appropriate hand tool in location where hydrogen is handled. As a consequence, whatever the tool used, it is always recommended to purge hydrogen before any intervention. Tools coated with shock absorbing materials can be a better option (as long as the coating material can not give rise to electrostatic sparks). Floor can also be covered with shock absorbing materials.

Finally the use of aluminium in contact with steel must be prohibited due to the highly energetic reaction that can takes place whenever aluminium gets into contact with rusty steel.

Hot work like grinding ignition mechanisms have been detailed above. The only difference between hot work and grinding ignition mechanisms being that hot spots and sparks are not generated by a process mechanical failure but by human activity. Whenever hot work takes place (welding, grinding…) a hot work permit should be required. This permit assesses any fire or explosion hazards in connection with the planned work and proposes prevention and protection means for risk control. Prevention typically implies to switch of any gas supply and to purge equipment… Examples of protection means are to have fire fighting equipment available and organising beats after work completion.

Beyond the delivery of a “hot work permit” people involved in hot work should be appropriately trained.

|

References S Hawksworth & all, « Ignition of explosive atmosphere by mechanical equipment », CEN/TC 305/WG 2 N0433, SYMPOSIUM SERIES No. 150, 2005 EN 60079-9 (2004) , « Electrical apparatus for explosive gas atmosphere : General requirements ». Norme EN 50014 : 1997 – Matériel électrique pour atmosphères explosibles – Règles générales EN 50281-1-2 : Sélection, Installation et entretien : Tmax admissible = 2/3 Tnuage ATEX Guide, TÜV Rheinland France Eléments pour un guide de sécurité hydrogène – Expérimentations spécifiques, Choix d’appareils adaptés – Volume 1 – Annexe 1 : Protection contres les étincelles d’origine mécanique, Rapport EUR9689 FR, année 1985 |

Different guidelines exist (CLC/TR 50404, NFPA 77) treating practical solutions in order to avoid the charge generation and accumulation phenomena and thus electrostatic discharge in various industrial situations. In a non-exhaustive way, we can recall the principle measures to adopt:

The first stage consists in avoiding, as far as possible, electric charge generation by one of the phenomena previously mentioned.

For the majority of nonconductive liquids, it is recommended not to exceed 1 m/s transport speeds, either by decreasing the flow of the pump, or by increasing the pipe diameter. This value will have however to be checked before its application in the case of hydrogen.

In the case of particles contained in a gas flow, it is not possible to prevent the electrical charging of these particles, but it is possible to prevent the accumulation phenomenon.

The second stage consists in avoiding the use of insulating materials (supports, valves, coatings, etc) and in putting all the elements of the installation at the same potential and in grounding them.

The use of insulating materials must be avoided, as far as possible, whatever its size. Indeed, a simple bolt has a capacity of 1 PF and its setting with a potential of 10 kV would be enough to produce a spark discharge of 50 J, sufficiently to ignite an air-hydrogen ATEX.

In the same way, the use of certified materials according to the category corresponding to predefined ATEX zones allows the use of safety material. Thus, a material of category 1 and valid for IIC gas group, to which hydrogen is attached, should not include surfaces higher than 4 cm2 of insulating material (according to EN 13463-1 standard).

Bonding will have to be made so as not have an insulated element able to accumulate electrical charges. The system will be connected to the ground in such way that the leakage resistance between an unspecified point of the installation and the ground will not exceed the threshold of 106 Ω. In practice, for the metal elements, this resistance is normally much lower than this value.

Taking into account the electrostatic risk from the electrical charged operators in the hydrogen industry is to be considered as for the semiconductors industry. Indeed these are very sensitive to the electrostatic discharges which can strongly damage them. Thus, the same type of equipment can be carried by the involved personnel: grounded bracelet, conductive shoes, antistatic fabrics, etc. The leakage resistance between a person and the ground should not exceed 108 Ω. However, it is important to note that the overriding principle with regard to personnel is that wherever possible, all precautions should be taken to ensure that they do not operate in an explosive atmosphere, or in an area where an explosive atmosphere is likely to occur.

Other measures (air humidification, ionisation), in order to limit the charge accumulation and discharge phenomena, exist but are not easily applicable in the case of installations handling liquid or gaseous hydrogen.

All measurements described in this paper would not be enough to prevent and protect the industrial installations from the electrostatic risk if the personnel were not trained accordingly and if technical improvements were not checked periodically. This step fits fully in the logic of the risks analysis required by 1999/92/CE European Directive transposed in each member state of the EU. The taking into account of the electrostatic risk is explicitly required there (1999/92/CE Directive, Annexe II §2.3), as well as the staff training concerned with ATEX risks (1999/92/CE Directive, Annexe II, §1.1).

The electrostatic charge and discharge phenomena are well-known for the majority of the combustible materials as for the various manufacturing processes and were briefly detailed above.

But the risks related to the intrinsic data of hydrogen (low MIE, low conductivity for liquid hydrogen) have not been studied in detail yet. The risks related to the accidental leak of compressed hydrogen is, a priori, one of the most probable sources of ignition for the ignition of air-hydrogen ATEX (Astbury and Hawksworth, 2005), but that remains to be shown.

The following of safety procedures and training of professional personnel involved in the handling of hydrogen systems are probably the most important of prevention measures to reduce the occurrence of and potential consequences of incidents or accidents. Such procedures and training exist today in the chemical industry where hydrogen is produced, handled, stored and transported. Similar procedures are therefore to be developed for new applications of hydrogen such as transport or energy conversion, for professionals who come into contact with hydrogen. For the public, specific education courses are needed to address the specific properties of hydrogen, compared to other more familiar fuels such as natural gas or gasoline. Having a basic understanding of how hydrogen behaves when accidentally released into the environment is a prevention measure that all stakeholders of hydrogen must follow.

All measurements described in this paper would not be enough to prevent and protect the industrial installations from the electrostatic risk if the personnel were not trained accordingly and if technical improvements were not checked periodically. This step fits fully in the logic of the risks analysis required by 1999/92/CE European Directive transposed in each member state of the EU. The taking into account of the electrostatic risk is explicitly required there (1999/92/CE Directive, Annexe II §2.3), as well as the staff training concerned with ATEX risks (1999/92/CE Directive, Annexe II, §1.1).

The electrostatic charge and discharge phenomena are well-known for the majority of the combustible materials as for the various manufacturing processes and were briefly detailed above. But the risks related to the intrinsic data of hydrogen (low MIE, low conductivity for liquid hydrogen) have not been studied in detail yet. The risks related to the accidental leak of compressed hydrogen is, a priori, one of the most probable sources of ignition for the ignition of air-hydrogen ATEX (Astbury and Hawksworth, 2005), but that remains to be shown.

Detection may consist in supervising an unattended site, or in monitoring signals that cannot be perceived by attending employees, with the aim of producing an action before an accident escalates. In the case of hydrogen fires, detection can fulfil both requirements. The major hazards due to an unwanted release of hydrogen relate to the build up of explosive conditions. In this respect, hydrogen is potentially more hazardous than other conventional fuels (methane, propane) or their vapors (gasoline) in most confined situations because of its high flammability, wide detonability ranges and its low ignition energy (CracknellRF:2002). Although its high buoyancy means that the risks of an unwanted release are likely to decrease rapidly to acceptable levels in outdoor situations and/or in areas where there is adequate ventilation, the deployment of an adequate system for the detection of explosive atmospheres should always be taken into consideration as a possible safety measure.

In regulatory terms, the issue of an explosive atmosphere is covered within the existing legislation for the safe use of flammable and explosive gases in general. Alongside other protection measures, the European Parliament and Council Directive 1999/92/EC on the Minimum Requirements for Improving the Safety and Health Protection of Workers potentially at risk from explosive atmospheres (Directive:1999:92:EC:2000) prescribes that “Where necessary, workers must be given optical and/or acoustic warnings and withdrawn before the explosion conditions are reached”. It follows that the necessity of installing a detection system should be estimated as part of a preliminary analysis of the operational hazards posed by the use of flammable gases. The point is further detailed in a subsequent Communication of the European Commission (COM:2003:515final) on the good practice for implementing the Directive, which states that “Concentrations in the vicinity of a plant can be monitored e.g. by means of gas alarms”. For such alarms to be used, the substances likely to be present, the location of the sources, maximum source strength and dispersion conditions must be known in sufficient detail and the instrument performance must be appropriate to the conditions of use, especially with regard to response time, alarm level and cross-sensitivity. Failure of individual functions of gas alarm systems should not lead to dangerous situations and the number and location of measuring points must be chosen to allow the anticipated mixtures to be detected quickly and reliably. Last but not least, gas alarms for use in hazardous areas must be approved and suitably marked as safe electrical equipment according to the European Directive 94/9/EC (Directive:94:9:EC:1994), which in turn is supported by a number of European standards prepared by CENELEC (EuropeanCommission:ATEXGuidelines:2007) annexes 5-7. While ensuring the safety of industrial operation in the presence of flammable gases is a well-recognized issue for which a number of established technologies can be used, there is a need to reconsider existing knowledge of hydrogen detection in the light of a future hydrogen economy. A wide variety of novel applications could be in sight, some of which may bring hydrogen much closer to the general public than it has ever been before, thus requiring hydrogen sensors to be as ubiquitous as computer chips in our society (DiMeoFJr:2000). Both, the U.S. Department of Energy (DoE) and the European Hydrogen Fuel Cell Platform (HFP), have been identifying new directions for hydrogen sensor development, envisaging innovation in both materials and concepts for applications ranging from large-area physical sensing to in-situ detection of leaks from portable devices (HFP:StrategicResearchAgenda:2005). Efficiency over a wide range of hydrogen (and oxygen) concentrations, low sensitivity to gaseous contaminants and poisoning are outstanding requirements, along with the possibility to efficiently integrate “intelligent” sensing devices into hydrogen systems, so that safety or emergency measures can be activated automatically where needed.

Several types of hydrogen sensors are in use, selected according to the operating conditions. Electrochemical, catalytic and thermal conductivity sensors are mainly used in industries where hydrogen risk is present. Semi-conductor-based sensors are most often used in research laboratories, whereas MEMS's (Micro Electro Mechanic System) are used in the aeronautic and space travel industries. The operating principles of commercially available sensorsand some other sensors which are under development are briefly described below.

The working principle is amperometry, i.e. the measurement of current driven by redox- (reduction-oxidation) reactions. The process is based on an electrochemical cell covered by a semi-permeable, selective membrane which enables the exclusive diffusion of hydrogen. The diffusion rate through this membrane is proportional to air temperature and to the partial pressure of hydrogen (and therefore to its concentration in air). Once it has diffused through the membrane, hydrogen comes into contact with the boundary layer between the membrane and the electrolyte which consists of sulphuric acid. The hydrogen is instantly ionised at the solid-liquid interface of a platinum catalytic electrode (working electrode). This ionisation enables a redox reaction with the second electrode (auxiliary electrode) consisting of platinum oxide. These reactions cause a potential difference between the electrodes which enables the hydrogen concentration to be determined by a non-linear correlation. The reaction products generate charge barriers which tend to restrict the reaction. To improve the stability and the reproducibility of the measurement, a third, chemically non-active electrode is added to the cell. A potentiostat (created by using an operational amplifier) is applied to maintain the potential of the working electrode at the same value as this third electrode, called the reference electrode. The lifetime of the amperometric cell is limited by a dry-out effect of the electrolyte which is strongly influenced by its exposure to certain operating conditions, especially raised temperatures. (AccorsiA:1994),(JamoisD:1997)

The detection principle is based on combustion heat measurement of flammable gas at the surface of a metallic catalyser. This means that a pearl covered with a catalyst (called a pellistor or catalytic pearl) or even a platinum filament is heated by the Joule effect while its electric power consumption is measured. Combustion of gas molecules at the element surface causes an increase in its temperature and therefore a change in its resistance. This resistance modification creates an imbalance in the Wheatstone bridge where the measurement element is inserted. Hydrogen concentration in air is linearely correlated to the imbalance of the bridge. To overcome the influence of variations in temperature and room humidity, a second element, similar to the one used for the measurement, but with a non-catalytic surface, is inserted into the Wheatstone bridge. In the absence of combustible gas, each of the two elements undergoes identical resistance variations and the bridge remains balanced. (AccorsiA:1994),(JamoisD:1997),(MoliereM:2005)

Heat conduction sensors use the high thermal conductivity of hydrogen gas. A material heated by the Joule effect is stabilised at a temperature which depends on the electrical power provided and thermal exchanges with the gaseous environment. A change in the composition of the atmosphere causes a change in the sensor temperature. The derivative of this temperature change, which varies the electrical resistance of the element, is linearly correlated to the concentration of hydrogen gas in air. For the measurement, a metallic wire conductor coated with chemically inert material is exposed to the gas probe. A second identical wire conductor is exposed to a reference atmosphere for temperature compensation. The electrical resistance variation is also measured using a Wheatstone bridge. Signals caused by the varying thermal conditions are weaker than the signals of catalytic sensors. (AccorsiA:1994)

The support material of the redox-reaction is no longer a metal, but an n- or p-type semi-conductor of metal oxide (SnO2, ZnO, etc.). Its conductivity is caused by shortages of oxygen (oxide not exactly stoichiometric). These redox reactions, or simply adsorption reactions on the surface, change the material resistance by modifying the number of oxygen shortages. The material is heated, similar to the catalytic pearls, but the measurement is different: The resistance variation of the material itself is measured rather than that of the heating element, which is linked to hydrogen concentration by a non-linear correlation. (AccorsiA:1994)

This sensor type is based on a metal oxide field effect transistor. Hydrogen diffuses into the transistor bulk, and its electrical properties change, dependent on the hydrogen concentration. Hydrogen presence induces an increase of the threshold voltage and a decrease of transconductance in an electrical connection as shown in Fig. 5. These transconductance changes are linked to hydrogen concentration by a non-linear correlation.

This sensor type consists of a catalytically active palladium surface. Hydrogen is adsorbed, dissociates to hydrogen atoms and generates palladium hydride, which has a higher electrical resistance than the pure palladium. This resistance change, which is linearely correlated to hydrogen concentration, is then measured. (TanOK:1999)

Micro electro mechanic systems combine calculators and miniscule devices such as sensors, valves, gears, mirrors and actuators loaded on a semi-conductor chip. The “detector” chip comprises

The operating principle of the Schottky diode is the following: the palladium enables the adsorption and the dissociation of the hydrogen molecule into hydrogen atoms. The hydrogen atoms diffuse through the palladium up to the PdCr interface and modify the surface charge. This change is detectable by measuring the voltage-current pair and is dependent on the hydrogen concentration by a non-linear correlation. In the case of a resistive sensor, the formation of palladium hydrides (caused by the adsorption and the dissociation of the hydrogen molecule into hydrogen atoms) increases the resistance compared to the pure palladium. (ChengSY:2003),(KimJ:2003),(ChenHI:2001)

Hydrogen detection technologies can generally be divided into non-optical and optical based technologies. The following section gives a survey on both, starting with non-optical technologies (TobiskaP:2001),(TanOK:1999). Recent technologies are

The development of semi-conductor and Schottky diode sensors mainly aims to improve the selectivity of the different layers as well as testing new metallic substrate–deposit combinations. Although these technologies are available on the market, research continues in order to reduce drift and to increase selectivity. The operation of semi-conductor and Schottky diode technologies is described above. Among others the operating principles of palladium wire network based sensors and surface sound wave sensors on a nano-structured sensitive layer are described. Emerging optical technologies mainly use fibre optics combined with hydrogen-sensitive coatings to measure hydrogen concentrations. (BaoX:1995),(BillingtonR:1999),(GlennSellarR:2003)

These sensors consist of a network of 20 to 100 palladium nano or mesoscopic wires. These networks of palladium nano-wires are prepared by electro-deposition on a graphite surface and transferred onto a glass slide covered with a cyanacrylate film. The nano-wires are then connected on either side by silver contacts. These palladium nano-wires are in fact “broken” and do not conduct the current. In the presence of hydrogen, the palladium swells slightly, and the nanoscopic spaces or “breakages” are “repaired”, enabling the passage of electric current. The resistance change depends on the hydrogen concentration, in a concentration range from 2 to 10%. In order to operate these sensors require a permanent power connection, and may even need to be heated. (FavierF:2001),(MatsumiyaM:2003)

A surface acoustic wave sensor is built around two interconnected transducers placed on the surface of a piezoelectric substrate. By connecting alternating current to the metallic conductors of the entrance transducer, an alternation of compressions and expansions occurs which generates a surface wave. This wave moves towards the second transducer to be converted back to an electric signal. During the transit between the two electrodes, it is possible to influence the wave by using a nano-structured sensitive net, which consists of the same palladium wire network mentioned in the previous paragraph. This network represents disruptions for the wave conducting surface and varies its physical characteristics (density, rigidity, electric conductivity, thickness) with absorbed hydrogen, which itself depends on the hydrogen concentration present. These disruptions lead to hydrogen concentration dependent phase speed and attenuation variations of the surface acoustic waves. Temperature dependencies can be minimized by comparison with the output signal of a second, identical sound wave sensor without an H2-sensitive Pd network.

This type of interferometric hydrogen sensor is based on a multi-modal fibre optic with a palladium micro-mirror. Hydrogen is absorbed by the palladium micro-mirror located at the end of the fibre. The optical and electric properties of the palladium change. Consequently, the reflected wave is modified whereas the incident wave remains the same. (BevenotX:2000)

Tungsten trioxide (WO3) shows hydrogen concentration dependent changes in its refractive index (BensonDK:1999), which leads to changes in the reflected light intensity. Resulting intensity variations of the reflected beam can be interferometrically detected.

The sensitive area is a fibre section covered with a thin palladium film. Light waves passing the fibre cause evanescent waves on the fibre core surface. Since the core of the fibre is covered with a palladium layer, the evanescent fields are altered. When hydrogen is absorbed by the palladium film, the refractive index of the Pd coating changes by reduction. This change in the refractive index modifies the absorption of the guided light, which can be detected by monitoring the light intensity via interferometer techniques like Fabry-Perot. (TabibAzarM:1999),(UttamchandaniD:1999),(KazemiAA:1999),(MaN:1999)

A Bragg network causes periodic or aperiodic disruption of the effective absorption ratio or of the effective refractive index of a fibre-optic cable. Predetermined light wavelengths are reflected by the Bragg network while all other wavelengths pass through it. In this sensor, which operates with UV light, a mechanical stress develops which is caused by the palladium layer when it absorbs hydrogen. This stress stretches or compresses the Bragg network and therefore the wavelengths or optical lengths of reflected or transmitted light. Where several Bragg networks with different lattice constants are used, several hydrogen sensors can be multiplexed on a single fibre. (SutapunB:1999)

This type of non-electric indicator consists of a thin film coating or a pigment of a transition metal oxide such as tungsten oxide or molybdenum oxide with a catalyst such as platinum or palladium. The oxide is partially reduced in the presence of hydrogen in concentrations as low as 300 parts per million and changes from transparent to a dark color. The color change is fast and easily seen from a distance. In air, the color change reverses quickly when the source of hydrogen gas is removed, in the case of tungsten oxide, or is nearly irreversible, in the case of molybdenum oxide. The partially reduced transition metal oxide becomes semi conductive and increases its electrical conductivity by several orders of magnitude when exposed to hydrogen. The integration of this electrical resistance sensor with an RFID (Radio Frequency IDentification) tag may extend the ability of these sensors to record and transmit a history of the presence or absence of leaked hydrogen over long distances. Over long periods of exposure to the atmosphere, the indicator’s response may slow due to catalyst degradation. Current emphasis is on controlling this degradation. Chemochromic sensors and their derivatives like paints, tape, cautionary decals and coatings for hydrogen storage tanks may be used to complement conventional electronic hydrogen sensors, or as a low-cost alternative in situations where an electronic signal is not needed for visual human surveillance. (HoaglandW:2007)

Table 1: typical hydrogen sensor properties

| Sensor Type Standard / Special | Hydrogen Concentration Range | Cross Sensitivity / Selectivity | Accuracy | Long-Term Stability | Response Time | Warm-up Time | Power Consumption | Costs |

| Electrochemical | 10,000 ppm | CO / high selectivity | 10% | - | < 1 min | 0.5 h | 1 mW | low |

| Catalytic bead | 100% LEL | Hydrocarbons, Combustible Gases & Vapours / low selectivity | 10% | o | < 0.5 min | 5 min | 1 W | medium |

| Heat Conduction / Catharometer | 100% Vol. | CH, CO2, He, Ar, Ne, SF6 / high selectivity | 0.5% | + | < 0.5 min | 1 min | 10 min | medium |

| Semiconductor | 100% LEL | low selectivity | 5% | -- | < 0.5 min | 5 min | 25 mW | very low |

| Field Effect Transistor | 30,000 ppm | high selectivity | 10% | - | < 10 s | 1 min | - | medium |

| Ultrasonic | 100% Vol. | low selectivity | 10% | o | 1 µs | 1 s | - | medium |

| Gas Chromatograph | 50% Vol. | very low / very high | 10% | - | 1 min | 3 h | - | very high |

| Mass Spectroscopy | 100 ppm -100% Vol. | very low / very high | 10% | + | 10 ms | 6 h | - | very high |

| MEM's | 10ppm -100% Vol. | low selectivity | 10% | - | - | - | - | high |

As a colourless, odourless and tasteless gas, hydrogen cannot be detected by human senses. Means should therefore be provided to detect the presence of hydrogen in places where leaks and/or accumulations may occur. The hydrogen detection system should be compatible with other systems such as those for fire detection and fire suppression. Hydrogen detection devices themselves should not be a source of ignition and the response times of these devices should be as rapid as possible. Some important performance factors to be considered when selecting a hydrogen sensor for a particular application include:

The correct location of reliable sensors is crucial for timely detection and warning of hydrogen leaks before an explosive mixture is formed. Recommended locations (ISO/TR 15916, 2004 (ISO:TR:15916:2004E)) for sensors include the following:

A generally accepted and commonly used concentration level for alarm activation is 1 % hydrogen (volume fraction) in air, which is equivalent to 25 % of the lower flammability limit. This level should normally provide adequate time for an appropriate response to be initiated, such as a system shutdown, evacuation of personnel or other measures where necessary. In designing a reliable hydrogen detection and monitoring system, the following recommendations have been made by NASA 1997 (NASA:NSS:1740:16:1997):

At a European level, and to the knowledge of the authors, no EN standard or recommendation for detection layouts specific to hydrogen systems has been made publically available so far. However, an obligation is posed under the ATEX directive (Directive:94:9:EC:1994) for the necessary instructions for detection or alarm devices for monitoring the occurrence of explosive atmospheres to be provided in the appropriate places. The European Standard EN50073 (EN:50073:1999) supporting the Directive provides details of the criteria for the selection, installation and placement of combustible gas sensors, which are essentially coherent with the information laid down in the previous paragraphs of the EN 50073. The international standard IEC 61779-6 (EN:61779-6:1999), very similar to the EN 50073, also provides a two-pages document in the annex that summarizes the above points in the form of a typical environmental and application check-list.

A detector includes two elements: a sensor and a transducer. The sensor is the sensitive element responsible for converting a physical value (e.g. gas concentration) into a useful output signal. The transducer turns the output signal into meaningful information displayed by the user interface. Sensor or / and transducer ageing may cause a drift with time. Maintenance is therefore essential to maintain the high performance level required for a safety applications.

Regarding maintenance, detectors should be:

Maintenance intervals depend on both the context of use and the type of detector involved (detection technique, portable or fixed detector…). The best way to determine the maintenance interval for a detector is based on experience gained through the use of this detector. For new installations, it may be wise to carry out maintenance frequently at first (perhaps weekly), increasing the time intervals (to, perhaps, monthly) as confidence grows on the basis of the maintenance records of the installation concerned. Information on the maintenance protocol should be found in the user manual. IEC 61508 (EN:61508-1:2001) also deals with the need for periodic maintenance.

Hydrogen burns with very pale blue flames and emits neither visible light in day time (solar radiation can overpower the light from a hydrogen flame) nor smoke (it produces water when it burns in air) unless, for example, sodium salt is added or dust particles are entrained and burned along with the combustible mixture. Compared to hydrocarbon combustion, hydrogen flames radiate significantly less heat and so human physical perception of this heat does not occur until direct contact is made with the flame. A hydrogen fire may therefore remain undetected and propagate despite human direct monitoring in areas where hydrogen can leak, spill or accumulate and form potentially combustible mixtures. Hydrogen fire detectors ensure that immediate action is taken in these situations. Hydrogen fire detectors can be either stationary for continuous monitoring of remote operations or portable for field operations.

For an efficient and reliable use, a hydrogen fire detector should fulfil the following criteria:

In terms of performance, its ability

should be considered when installing a hydrogen flame detector.

For instance, NASA (NASA:NSS:1740:16:1997) indicates that a fire detection system should at least be capable of detecting, at a minimum distance of 4.6 m, the flame from the combustion of 5.0 l/min of gaseous hydrogen at NTP flowing through a 1.6 mm orifice to produce a 20 cm high flame.

A hydrogen fire can potentually be detected by using thermal detectors (such as rate-of-temperature-rise or overheat detectors) to pick up radiative, convective or conductive heat. These reliable detectors of various types are suitable for hydrogen fire detection as long as they are located very near to where the fire breaks out. Other common fire detector types such as those with ionising cells, are not appropriate for detecting hydrogen fires.

Though hydrogen fires tend to emit radiation over a broad range and are not characterised by extreme peaks, hydrogen fire detectors can also rely on UV and IR light detection. Beside the radiation itself, hydrogen flames can be indirectly visible by their strong heat effect and turbulence - “heat ripples” - of the surrounding atmosphere. Optical flame detectors detect specific spectral radiation emitted during the combustion process by the various chemical species (ions, radicals, molecules) that are either intermediates or final products of combustion. Chemical species emit radiation at wavelengths characteristic to the particular species.

These detection techniques assume that no interfering shield is placed between the flame and the UV / IR detector. Though optical techniques are available to pick up these various wavelengths, the main challenge consists in ditinguishing hydrogen flame signals from other potential sources that emit signals with a similar frequency and intensity.

UV systems are preferable to IR systems because they are extremely sensitive. In addition, the probability of encountering an interfering signal is lower as long as UV detectors are shaded from sun light. Drawbacks are on the one hand the cost and on the other hand the reduced efficiency with liquid hydrogen flames, as fog blocks UV rays. The same applies whenever fog is present. False alarms can be triggered by random UV sources such as lightning or arc welding.

The ability of the detector to discriminate sunlight-induced UV radiation from hydrogen flames to avoid false alarms is the main challenge. Various techniques can be applied:

It was mentioned above that fog may hinder UV transmission to the sensor cell. IR detectors are not affected by this issue. In addition, hydrogen flames emit sufficient IR for their detection with IR sensors. The main challenge remains the same as before: i.e. discrimination between IR related to a hydrogen fire and IR from the sun, any light sources or any hot materials. IR sources powered with alternating electric currents can be filtered due to their own 100 Hz modulated signal. However, neither hot bodies nor sunlight display a modulated signal that can be picked up and filtered. A solution consists in focussing on the 1.7 µm wavelength that corresponds to a peak emission of steam, bearing in mind that the atmosphere absorbs sun-emitted IR wavelengths between 1.81 & 1.88 µm and between 2.55 & 2.9 µm. The 1.7 µm wavelength is the only one of the three IR peaks mentioned above that falls within the IR filtering spectrum of the atmosphere. Figure 13 is taken from (NASA:NSS:1740:16:1997) and clarifies this situation comparing atmospheric transmission with hydrogen-air flame emission in the IR range.

Thermal detectors, e.g. temperature sensors, detect the heat of the flame. Such detectors need to be located very close to or at the site of a fire and are not specific to hydrogen flames.

Imaging systems mainly are available in the thermal IR region and do not provide continuous monitoring with alarm capability. A trained operator is required to interpret whether the image being viewed is a flame. UV imaging systems require special optics and are very expensive.

Rescue services or maintenance teams use brooms as a simple method to locate small fires. The intent is that dry corn straw or sage grass broom easily ignites when it comes into contact with a hydrogen flame. Also non flammable objects or dust particles in a hydrogen flame cause the flame to emit radiation in the visible spectrum. Dirt and dry fire extinguishers have been used for this purpose, but extreme caution needs to be taken with such practice due to the required proximity to the flame.

However, it must be underlined that it is still a challenge for surveillance sensor developers to distinguish hydrogen-related signals from parasitic ones. To prevent false alarms and related automatic actions, in critical cases it si still an option to apply human analysis and actions in preference automatic ones.

Invalid BibTex Entry!

|

Contributing author |

Main contributions | Organisation | e.mail |

| Olav Hansen | Chapter coordinator

Various contributions | GexCon | olav@gexcon.com |

| Vladimir Molkov | Venting guidelines example | UU | V.Molkov@ulster.ac.uk |

| Miyahara | Protection wall example | Obayashi Corporation | miyahara.hideo@obayashi.co.jp |

| Angunn Engebø | Emergency response | DNV | Angunn.Engebo@dnv.com |

|

Andrzej Teodorczyk | Flame & detonation arresters, safe gap | WUT | ateod@itc.pw.edu.pl |

| Karl Verfondern | Liquid spill | FZJ | k.verfondern@fz-juelich.de |

When handling hydrogen there are usually a number of unwanted potentially hazardous events that can take place with a certain frequency. The total sum of all consequences weighted by their frequency is normally referred to as the risk. This chapter will discuss various ways and methods that can potentially reduce the risk from unwanted events (i.e. a reduction of frequency and/or consequences).

Consequences can include loss of life or injuries to people, property as well as reputation and more. The measurement unit for risk can be e.g. money, as all consequences may have a estimated price. Quite often, though, a risk assessment will focus on potential for loss of life.

There are a number of possible unwanted events when handling hydrogen. Depending on setting and surroundings, the hazard will vary strongly. While a significant leak of hydrogen gas may be harmless in an unconfined process plant scenario because all gas is rapidly disappearing due to its buoyant nature, a much smaller leak may lead to a disaster if ignited inside a building. Examples of hazardous events are e.g.

Pressurized pipeline or vessel: Major rupture may this give strong shockwaves as well as significant loads due to dynamic pressure from the flow out of the pipeline. If ignited, fire may produce heat loads and radiation. Significant leak rates may lead to severe explosion scenarios with pressure effects in case of delayed ignition.

Liquid hydrogen storage: If released the low temperature of the hydrogen can cause damage to surroundings. If container is exposed to a fire, a too rapid heating relative to overpressure venting can lead to a BLEVE with significant overpressures and fireball with heat and radiation loads if ignited. Releases in water can result in rapid phase transition (RPT) explosions with associated overpressures. Liquid releases of hydrogen can also lead to significant release rates, and may in some circumstances show dense gas behavior, which may lead to major fires or explosions with associated pressures and heat loads.

Smaller releases may build up gas and lead to strong explosions inside confinements, in addition to smaller releases from hydrogen storage, transportation or equipment, utilities, these releases could come from batteries, nuclear radiation in water, electric arcs in oil, waste treatment (metal containing ash into water).

One major concern is usually the pressure effects, secondary effects such as projectiles and building collapse are generally more of a concern than the direct pressure effects on people. Consequences like explosion wind, fire heat loads as well as asphyxiation may also be important for the risk.

This section will aim at discussing and describing possible ways and methods to reduce the risk from unwanted events. It can sometimes be useful to separate between passive and active measures. A passive measure is already in place and activated when the unwanted incident takes place, whereas the active measure requires some kind of detection and activation before it is applied. Due to the nature of hydrogen, with the wide flammability and high reactivity, the use of active measures can be a challenge. In risk assessments one will normally also include a certain probability that the active system fails to activate. Measures discussed can either be applied to mitigate, control or prevent the event (fire triangle approach removing oxygen, ignition or hydrogen), or to protect people or equipment from the consequences of a given event. Some examples of protection measures are indicated.

Since the list of possible scenarios is very long, this selection will not cover all possible ways of reducing risk. One very important thing to notice is that some of the measures may seem contradictory from a risk point of view, and it is not obvious whether risk is reduced or increased. Examples are removal of ignition source vs. ignition on purpose. If gas clouds are always ignited small, the frequency of explosion may be increased, but the consequences likely reduced, giving a hopefully acceptable risk. Another example is increased confinement, which can reduce cloud size, but will often increase pressure and probability of unwanted consequences.

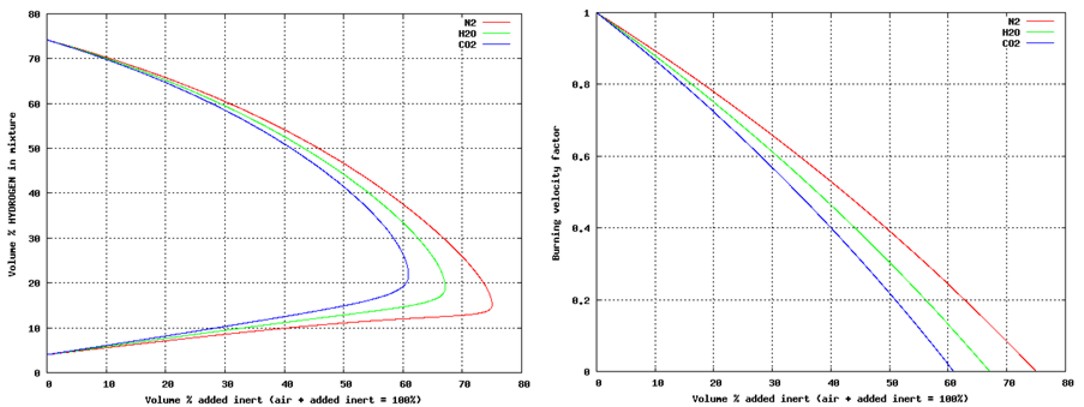

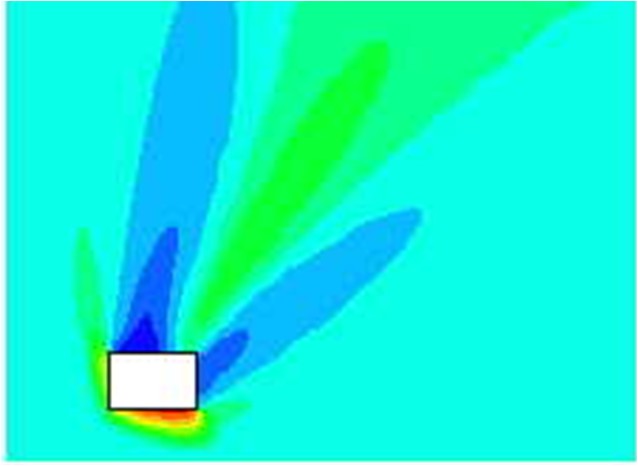

Most of the previous work on protection measures has been focusing on less reactive hydrocarbon gases or even dusts. Because the properties of hydrogen are very different (order of magnitude lower Minimum Ignition Energy, much wider flammability, much higher burning velocity, more likely to detonate, more difficult to inert and more), it is not obvious that these measures will do any good mitigating hydrogen. Important aspects are:

A further general problem with mitigation systems is that they are generally tested for idealized situations (empty spherical vessel with central ignition), but then applied in real life situations for which geometry will influence performance.

It may therefore be necessary to focus more on preventive measures, apply safety methods that exploit the buoyancy effects, and also put more weight on creative passive ways to reduce risk. The latter can be e.g. “soft barrier” methods [Tam, 2000] to reduce the size of dangerous flammable clouds, avoid flames to burn into congested areas, and also fill parts of the volume with inert balloons that will reduce combustible volume, but be compressed when overpressure builds up. A further discussion on such measures will be found in a later section.

|

Reference and sources [Tam 2000] Tam V (2000), Barrier Method: An Alternative Approach to Gas Explosion Control, FABIG Newsletter, R372, The Steel Construction Institute, UK |

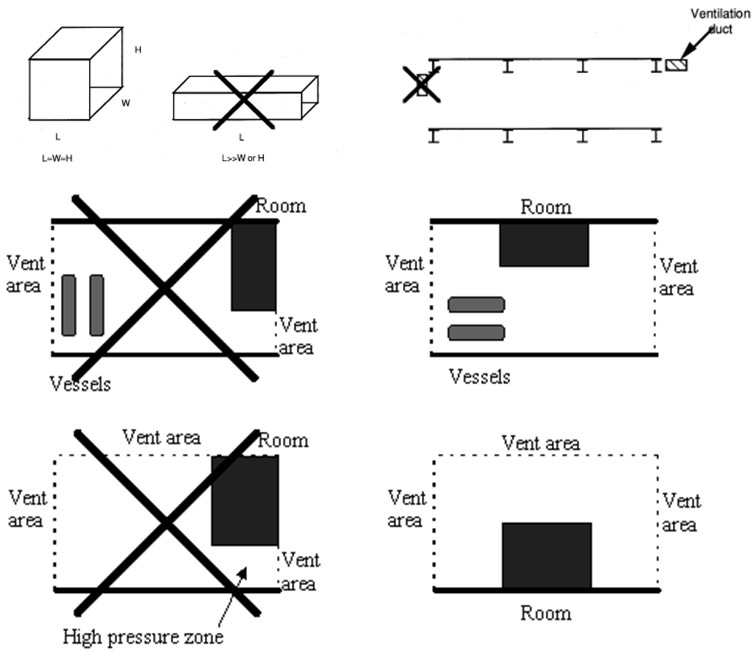

Venting of deflagrations is recognized as a most widespread and cost-effective explosion mitigation strategy. The methods are based on the two following observations/assumptions:

The leading “Venting of Deflagration” guidelines from the USA, NFPA-68 [NFPA-68, 2002], has history back to a temporary explosion venting standard from 1945. NFPA-68 has been updated with input from various sources, much of this is done in Europe with very significant contributions from Germany [Bartknecht 1993]. Based on numerous experiments and analytical considerations vent nomograms were developed for numerous dusts as well as some gases, including hydrogen.

When developing vent guidelines and nomograms, a number of assumptions, simplification and limitations will have to be defined. Since the flammables shall be categorized by reactivity, it is important to avoid situations where the flames get too turbulent, e.g. due to flame accelerating objects inside the room, or because the length/diameter ratio is too large. For this reason such guidelines will normally require that there are no obstructions inside the room and a maximum aspect ratio to be valid. This way, a significant part of the real life scenarios to be protected will fall outside the limitations of such guidelines. Other situations which may be difficult to cover with simple analytical equations or nomograms include the use of vent ducts, connected vessels, layout (geometry/vent distribution), non-ideal conditions (elevated or reduced temperature, pressure and oxygen concentration) and more.

In a recent effort to improve the venting guidelines and reduce the number of situations where these can not be applied, a new European Vent standard prEN14994 [prEN14994 2004], has been developed. This has been available in a draft version since 2004.

In NFPA-68 relations exist for hydrogen, but only for strong enclosures and with no turbulence generating obstructions. Similarly the prEN14994 can calculate relations for hydrogen, but only for situations “essentially free for turbulence generating obstructions”, with aspect ratio L/D < 3 and only allowing vessel strength of up to 2 bar. The possibility to use these standards and guidelines for the dimensioning of practical hydrogen applications may therefore be limited. The strict limitations when handling hydrogen are based on experimental observations, the presence of small objects or deviations from required shape of vessel may increase the severity of explosions dramatically. Experiments [Pförtner, 1985] have shown how the flame exiting from a vented vessel may experience a deflagration to detonation transition outside the vent, and [Dorofeev, 1995] showed that a detonation may be initiated inside the vent. In at least one of the experiments in the FLAME facility [Sherman, 1989] DDT and detonation flames inside the geometry may have been caused by lateral venting. For most situations with flammable gas either outside or inside a building/vessel, this may not be too much of a concern.

More detailed information about the various standards and guidelines can be found by reading them.

Standards and guidelines will usually be based on a coarse description of a room/vessel and the important parameters. Detailed layout, vent position, geometry and likely ignition location may be poorly described. One should therefore expect that the guidelines in most cases will give a conservative estimate of the expected overpressure, if applicable at all. Computational Fluid Dynamics (CFD) has a better possibility to describe the actual situation, including the situations not covered by the guidelines. One should in general expect to be able to reduce conservatism when applying more advanced methods. From CFD it is also possible to obtain more details about pressure loads, like duration, shape and distribution, and further how the venting will influence blast pressures and drag loads outside the vent openings. As the quality and applicability of CFD-tools vary significantly, one should make sure that the CFD-tool is properly validated against a wide array of relevant experiments, and also that validation based user guidelines exist and are followed by the user.

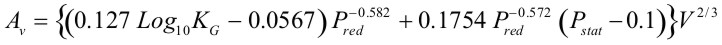

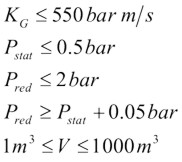

The current edition of NFPA 68 (2002) includes the vent sizing correlation, which reflect results presented by Bartknecht [1993]. The test data used in support of the correlation covered a range of volumes from 1 to 60 m3 and four gases: methane, propane, city gas and hydrogen. Additional testing was also carried out to study the effect of increasing values of vent relief pressure, Pstat. The result of all this work is summarized by the following formula: